Alstom found it hard to find qualified workers in Ottawa to build its light rail vehicles for the new system in the national capital.

Provincial Canadian content rules and a lack of trained manufacturing workers in Ottawa were sources of significant delay in building trains for the Confederation Line, according to the final report of the Ottawa Light Rail Transit Public Inquiry.

Ontario’s 2008 CanCon law stipulates that 25 per cent of the overall value of the system’s Alstom Citadis Spirit vehicles in both material used and labour employed to build them had to come from within Canada. Not meeting that threshold would put the province’s $600-million commitment to the overall cost at risk, the report said.

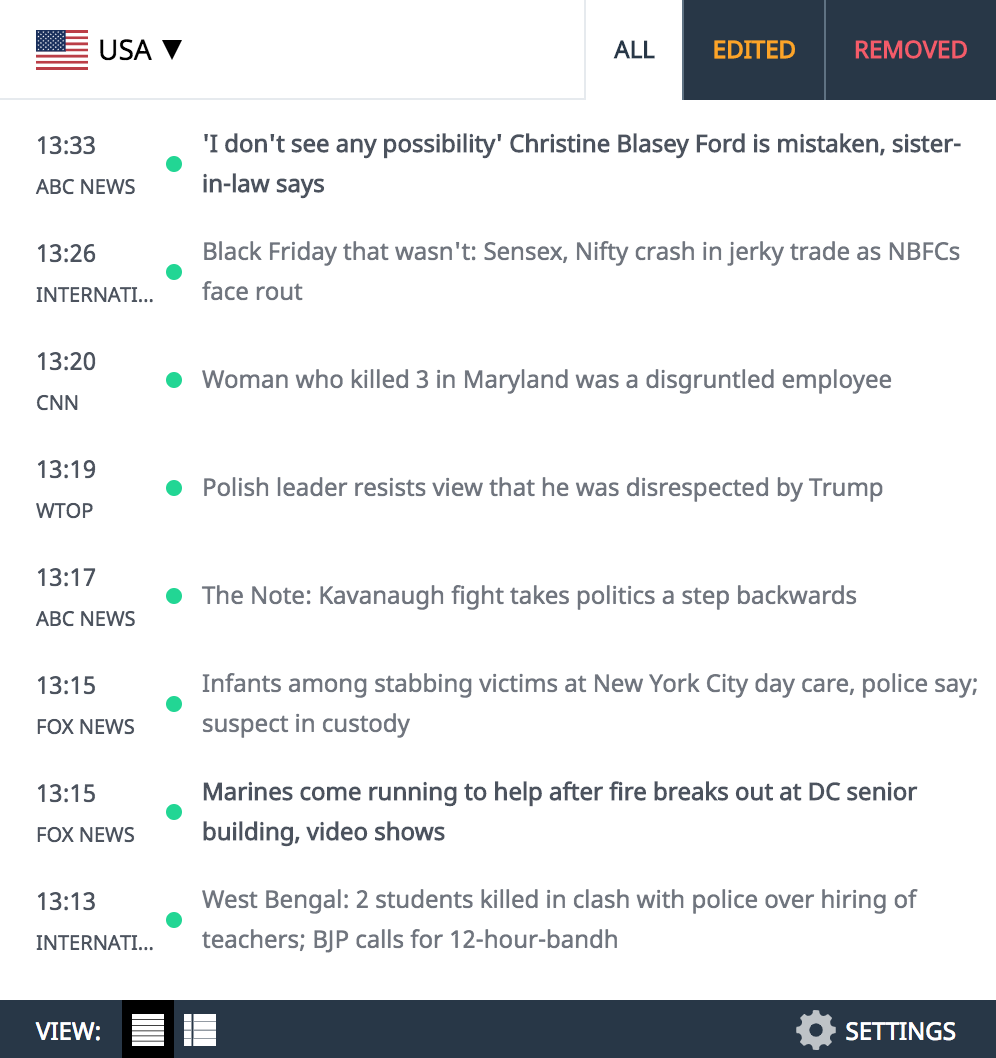

Sign up to receive daily headline news from Ottawa Citizen, a division of Postmedia Network Inc.

Thanks for signing up!

A welcome email is on its way. If you don't see it, please check your junk folder.

The next issue of Ottawa Citizen Headline News will soon be in your inbox.

“The Canadian content requirement gave Alstom no choice but to work with Canadian suppliers,” Justice William Hourigan wrote in his report, released Wednesday.

That was fine with Alstom — it had been planning to get a manufacturing foothold in the North American market — but the company found it hard to find qualified workers in Ottawa to build its light rail vehicles.

“There was no broad pool of skilled labour available to draw from in Ottawa — a city whose economy is not focused on manufacturing, much less on the specialty of train manufacturing,” Hourigan wrote.

Those who were hired were sent to New York for training. That gave them the necessary skills, but not the experience to deal with unexpected complexities.

“Still, the relative inexperience of the workforce had the potential to lead to quality issues that would be less likely to occur with a workforce that has been building trains for years,” Hourigan wrote. “In the case of the OLRT1 project, the inexperience of the workforce may have resulted in problems, such as defective wiring that then had to be fixed, adding to delays.”

Adding to Alstom’s difficulties was that its Ottawa shop would build the first cars for the LRT, then would become just a maintenance facility. That made it hard to attract employees.

As one Alstom executive told the inquiry: “It becomes very problematic to cycle up a workforce of 100 to 150 people for 18 months to two years … and then say, ‘Goodbye, we don’t need you.’”

In some cases, Canadian-manufactured parts were inferior to those built by Alstom’s more experienced European suppliers, the report said.

There are benefits to CanCon laws, including fostering economic development, shortening the supply chain and creating skilled manufacturing jobs. “As a general matter, the local content requirements are to be encouraged,” Hourigan wrote.

But he recommended the province allow waivers and exceptions to its rules to allow for problems of labour shortages and to ensure “transit operators are able to obtain a quality product produced by a qualified workforce and for the public interests.”