V-22 Osprey Crash Linked to Potential Metal Defects in Gearbox

A fatal V-22 Osprey crash in 2023 may be connected to metal weaknesses in a critical gear. The incident has led to extensive investigations and flight restrictions for the unique aircraft.

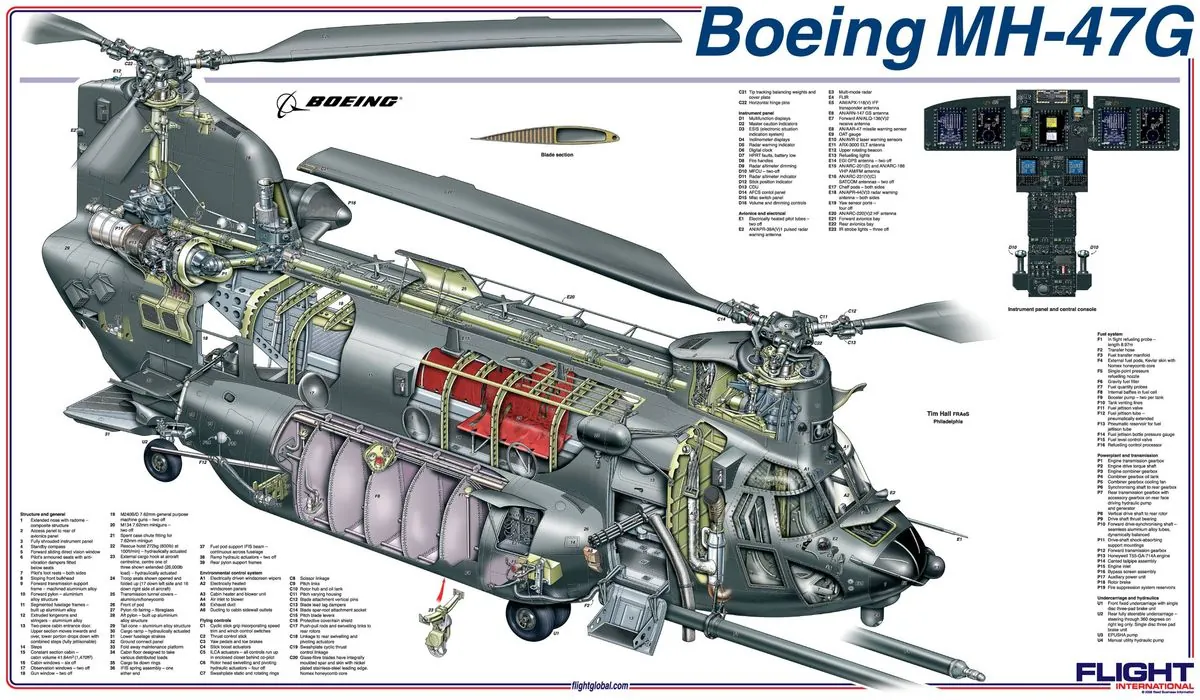

The V-22 Osprey, a unique aircraft capable of both vertical takeoff and high-speed flight, has faced scrutiny following a fatal crash in November 2023. This incident, which resulted in the loss of eight Air Force Special Operations Command service members, has been linked to a gear crack in the aircraft's proprotor gearbox.

Investigations have revealed that weak spots in the metal used to manufacture a critical component may have contributed to the accident. This marks the second fatal crash in less than two years attributed to failures in the Osprey's proprotor gearbox system, which functions as the aircraft's transmission.

The V-22 program office and Bell Flight have initiated efforts to address issues with this critical system. Some components have been wearing down earlier than anticipated, prompting a comprehensive review of the aircraft's design and maintenance procedures.

Data obtained through the Freedom of Information Act indicates that 609 proprotor gearboxes have been removed for repair over the past decade. In the last five years alone, the Marine Corps, Navy, and Air Force have reported 60 incidents involving this crucial component.

The Air Force has identified cracking in a pinion gear as a factor in the recent crash. This small but vital part, approximately the size of a large jar lid, plays a critical role in the Osprey's unique propulsion system. Investigators have found evidence of inclusions - microscopic weak spots in the metal caused by foreign substances during manufacturing - in the failed pinion gear.

Lt. Gen. Michael Conley, head of Air Force Special Operations Command, emphasized the challenges in detecting these defects, stating, "In the field, there's nothing we could have done to detect this." The sealed nature of the gearbox and the microscopic size of the inclusions make on-site inspections impractical.

In response to these findings, the Air Force has implemented more restrictive flying protocols for the Osprey. Until at least mid-2025, the aircraft will be required to stay within 30 minutes of a landing spot, among other safety measures.

Despite these challenges, the Osprey continues to play a vital role in military operations. Its unique design allows it to reach speeds of up to 316 mph and carry up to 24 troops or 20,000 pounds of internal cargo. The aircraft has been deployed in various military operations, including missions in Iraq, Afghanistan, and Libya.

The ongoing investigation and efforts to improve the Osprey's reliability underscore the complexities involved in developing and maintaining advanced military aircraft. As the V-22 program moves forward, balancing the aircraft's unique capabilities with ensuring crew safety remains a top priority for military leadership and manufacturers alike.

"As improved materials become available, they are evaluated for use in all our systems."

This statement reflects the ongoing commitment to enhancing the Osprey's safety and performance through technological advancements and rigorous testing procedures.