Port Talbot's Last Blast Furnace Closes, Marking End of an Era

Britain's largest steelworks in Port Talbot shuts its final blast furnace, ending over a century of traditional steelmaking. The closure, part of a decarbonization plan, impacts nearly 3,000 jobs.

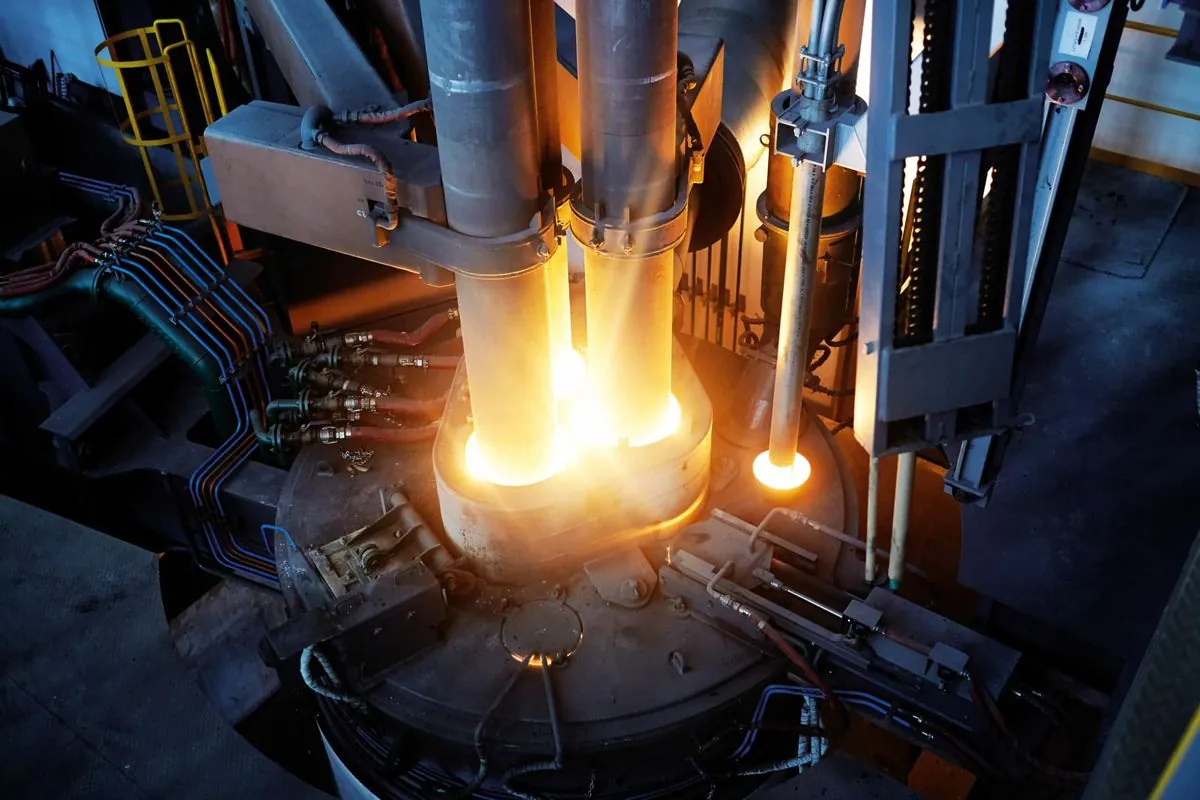

On September 30, 2024, Britain's steel industry marks a significant turning point as the last blast furnace at Port Talbot steelworks in Wales ceases operation. This closure brings an end to over a century of traditional steelmaking at the site, which was once Europe's largest steel plant.

The shutdown of Port Talbot's final blast furnace signifies more than just the end of an industrial era; it represents a major shift in Britain's industrial landscape. Established in 1901, Port Talbot Steelworks has been a cornerstone of the UK's steel industry for generations. At its peak in the 1960s, the facility employed approximately 20,000 workers, highlighting its historical significance to the region and the nation's economy.

Tata Steel, the Indian conglomerate that acquired the Port Talbot plant in 2007, has been grappling with significant financial challenges. The company reported losses of £1 million per day before initiating the closure process. This financial strain underscores the broader struggles faced by the UK steel industry, which has been in decline since the 1970s due to increasing competition from low-cost imports.

The closure will result in the loss of nearly 3,000 jobs, a stark contrast to the plant's heyday. However, Tata Steel is not abandoning the site entirely. The company has unveiled a £1.25 billion decarbonization plan, supported by £500 million in government funding. This initiative aims to transform the facility over the next three to four years by installing an electric arc furnace for scrap steel production.

Electric arc furnaces represent a significant leap in steel manufacturing technology. Invented by Paul Héroult in 1900, these furnaces can recycle up to 100% scrap steel and typically produce only one-seventh of the CO2 emissions compared to traditional blast furnaces. This transition aligns with the UK government's ambitious target to achieve net-zero emissions by 2050.

The shift at Port Talbot is part of a broader industrial transformation in Britain. Coincidentally, on the same day, the country's last coal-fired power plant is also shutting down, marking the end of over 140 years of coal-powered electricity generation in the UK. This simultaneous closure emphasizes the nation's commitment to reducing its carbon footprint.

The UK steel industry, despite its challenges, remains a significant contributor to the national economy, adding about £2 billion annually. As of 2024, it directly employs approximately 33,700 people. The government has pledged to invest £2.5 billion in the sector and plans to publish a comprehensive strategy for boosting the industry in the spring of 2025.

While Port Talbot transitions, other steelmakers in the UK are also considering similar moves. British Steel, owned by China's Jingye Group since 2020, continues to operate two blast furnaces in Scunthorpe, northern England. However, the company is in discussions with the government about transitioning to cleaner manufacturing methods.

The closure of Port Talbot's last blast furnace is expected to have a significant environmental impact. As the country's largest single carbon emitter, its transformation is projected to reduce Britain's overall carbon emissions by 1.5%. This substantial reduction underscores the importance of the steel industry in the nation's efforts to combat climate change.

"This is the end of an era. It's an incredibly sad and poignant day."

As Britain bids farewell to traditional steelmaking at Port Talbot, the industry stands at a crossroads. The challenge now lies in balancing the transition to greener technologies with preserving jobs and maintaining the UK's industrial capabilities. The success of this transformation will likely shape the future of British manufacturing and its role in a low-carbon economy.